Meet My Home-Made Buddy, Frank

Frank is a Computer Numerically Controlled (CNC) milling machine named after Dr. Frankenstein because all of the various parts used to build Frank came mostly from parts I already had. I made the first version of Frank back in 2009. Since then he has grown up and gotten stronger. Frank is now the most useful and fun tool I have ever owned.

I still have loads of fun out in my workshop building wood projects by hand. But Frank offers accuracy that I cannot even dream of when using hand tools. I could not build certain projects without the accuracy offered by computer modeling and CNC machining. Aligning many parts and integrating electronic items needs accuracy in the one one-thousandth inch (1-mil) range. I make my straight-edge wood inlays for example with a 2.5-mil clearance between the combined pieces. Human hair is about 3-mils thick. Building or changing electronic circuits needs all the accuracy that Frank offers.

His Early Years

I bought a desktop Sherline milling machine back in 2008. I converted that machine to CNC operation which opened a whole new world of capabilities. One major problem was the backlash on all three axes which is typical problem encountered when using lead screws. For example if the X-axis moved from left to right then a lead screw would have to rotate a significant amount from the leftmost position before the X-axis began to move to the right. That's backlash, and it is difficult to deal with. It was clear that I had to remove the backlash if I wanted to make inlays or anything else needing precision cuts.

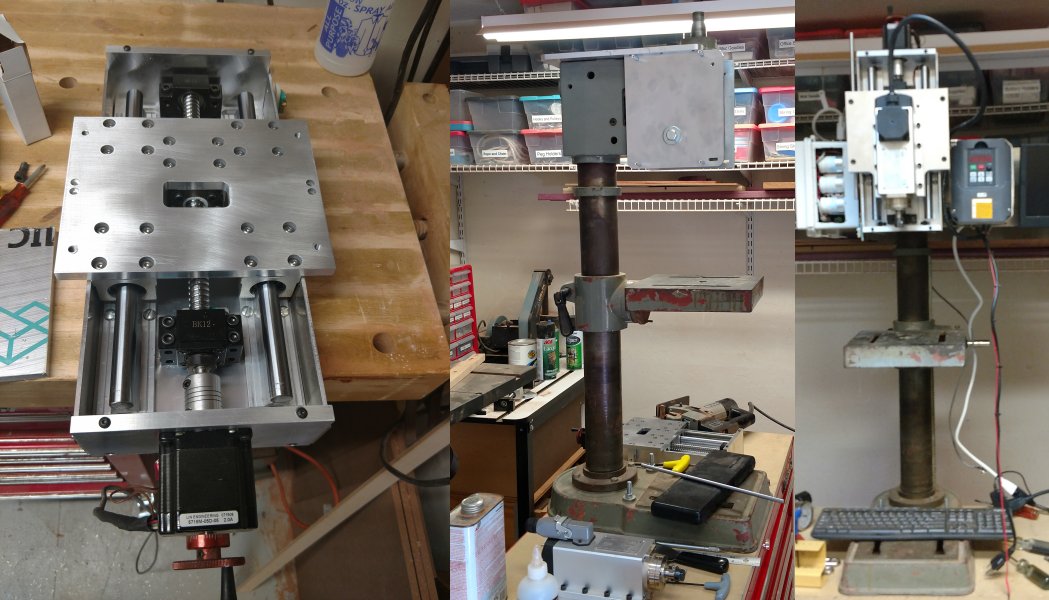

Lead screws are threaded rods with threaded nuts. Removing backlash requires ball screws which are like lead screws with ball-bearing nuts riding in precision helical groves. I built a completely new machine using ball screws to control the motion of each axis. I made a Z-axis slide using linear bearings and a ball-screw I found on eBay. I mounted the Sherline spindle to the new slide and assembled all those items to a piece of T-stock aluminum serving as the Z-axis column. I found two other ball-screw/pillow block slides on eBay and modified them to serve as the X-axis and Y-axis. This is when I named the machine "Frank" after Dr. Frankenstein because of all the various parts coming from all different locations.

Using ball-screws fixed the backlash problems and I enjoyed using Frank with his outstanding accuracy and repeatability for many years. But Frank still had limited cut lengths and a springy Z-axis column. The heavy T-stock aluminum was strong about the three X, Y, and Z-axes in a static sense, but it had poor torsional strength. It acted too much like a twisting spring when making cuts which caused excessive tool chatter. I had to make light, easy cuts to keep the tool chatter at bay.

Final Build

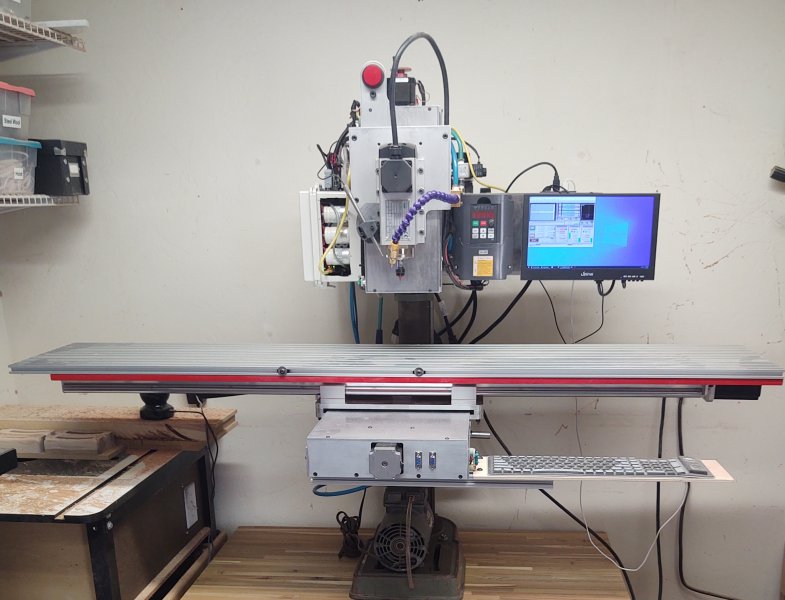

Frank had limited travel on all three axes which limited the size of projects I could build and I was getting a little impatient with the tool chatter issue. I decided to buy an old used drill press with a large tubular column and cast-iron head as the foundation for building a new machine. A tubular column provides excellent torsional stiffness and good static stiffness on all three axes.

At this point Frank could cut aluminum if the cuts were shallow and slow. I made a new Z-axis slide using Frank to cut out the aluminum parts. The left side of the picture below shows the completed Z-axis slide with the top cover removed. I installed the new slide onto the drill press head and moved the X-axis and Y-axis components from the smaller machine over to the new drill press project.

I now had extra rigidity and strength with the new drill press machine. I used this stronger machine to make all the parts needed for two larger slides. I designed the top of the new Y-axis with wide pillow-block supports to allow a much longer and heavier X-axis slide.

Frank is reliable enough to run unattended for many hours at a time, and accurate enough to build my most intricate projects. This machine was well worth all effort I put into it as it has opened an amazing new world of possibility to turn ideas into reality. Frank helps me feed my passion for building things, which is a passion I have had since as long as I can remember.